BETTER TOUCH BETTER BUSINESS

Contact Sales at Bayard .

The first step of the construction process of inorganic terrazzo floor: basic treatment

[Guide]: 1. Detection of water content in the grassroots level; 2. Flatness detection and treatment; 3. The detection and treatment of empty shells and weak places; 4. Detection and removal of stains; 5. Polished; 6. Various gap treatments.

Before the construction of the inorganic terrazzo floor, we need to carry out various inspections and treatments on the base layer of the ground. Only by perfecting the base layer can we ensure the smooth progress of the overall project in the later stage.

Detection of water content in the grassroots

Use the humidity electronic detector to conduct a comprehensive inspection of the construction area to see if it meets the requirements of the moisture content of the grassroots.

Flatness detection and processing

1. Use a long straightedge and feeler gauge to make a comprehensive survey of the mortar base in the shape of a well. You can also use a level to measure on-site level, measure according to the axis and make a record.

2. The height difference existing on the side of the column and the corner of the wall shall be clearly marked where it exceeds the standard.

3. After the inspection is completed, use a smoothing machine to grind the surface into a rough surface, and the flatness of the base layer should be controlled within 2mm-3mm.

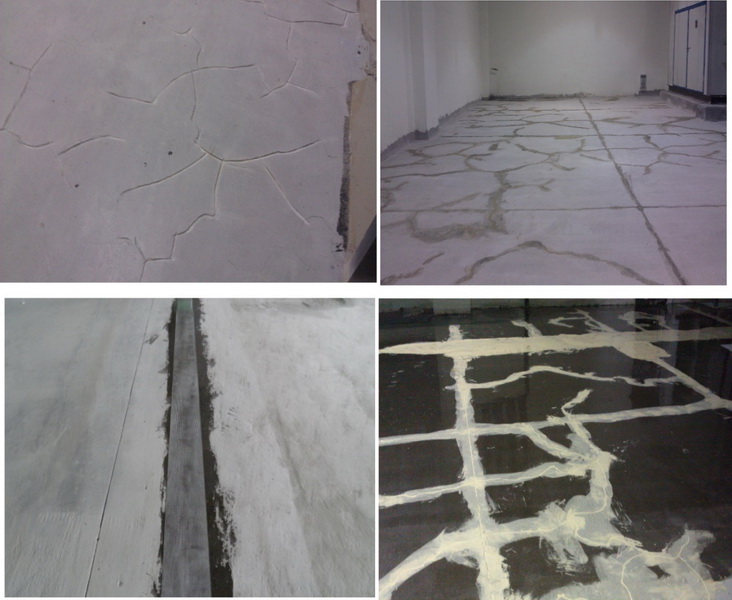

Detection and treatment of empty shells and weak places

1. Use the ground detection tool to tap along the ground in the shape of a well, and it is found that there are empty shells and partially unknotted objects to mark and remove them.

2. If there is an empty shell and other problems, it should be repaired with Boweit repair mortar.

3. After repairing, curing and drying should be carried out to ensure that the newly repaired concrete and the original base layer are well bonded.

Detection and removal of stains

1. Slight oil pollution can be polished and cleaned with a high-efficiency degreasing agent, and then use a blower (or hot air) machine to dry the cleaned base layer to make the moisture content meet the construction requirements.

2. For the part where the oil pollution is too deep, the contaminated part can only be completely removed, and then new concrete can be repaired.

3. For different stains, other contaminants on the surface should be cleaned or mechanically removed with different cleaning agents.

Various gap treatments

1. Find out the construction joints for mortar pouring according to the construction drawings

2. Carry out the expansion joints straighter, pay off and cut, the depth is more than 15CM.

3. Knock out the weak places on the seam, and then perform vacuuming and repairing.

4. After the repair is completed, put the line and cut it, the depth is more than 15CM, fill in the foam strip, and make the expansion joint mark.

Sanding requirements

1. The appearance of the bottom layer should be solid, free of scum, and clear lines.

2. The floating slurry and loose layer on the outer surface of the bottom layer should be completely removed.

3. If the corners of the wall cannot be polished by large equipment, they need to be polished with an angle grinder until the lines are revealed.

Precautions

1. When paving the inorganic terrazzo floor, the moisture content and flatness of the base concrete should meet the requirements, be firm, free of sand, free of shells, clean, free of stains, and free of cracks.

2. The concrete should be poured according to the proposal of our construction project manager, so that the reserved position of the expansion joint and the reserved joint of the final product are at the same position, which can reduce the incidence of concrete cracking.

3. The concrete must be C30 or above, and the curing period shall not be less than 25 days after pouring.

The above construction steps are completed.

The second step of the construction process of inorganic terrazzo floor: surface treatment

[Guide]: The function of the interface layer is to improve the physical and technical performance and process the surface of the object. Many problems such as hollowing and cracking will occur in the later stage of the project. The root cause is the unqualified treatment of the interface layer, which leads to a large increase in the later stage of the project.

The function of the interface layer is to improve the physical and technical performance and process the surface of the object. Many problems such as hollowing and cracking will occur in the later stage of the project. The root cause is the unqualified handling of the interface layer, which leads to a large increase in the later stage of the project and even delays in the delivery time. Therefore, we must pay attention to the above matters.

Laying the interface layer

1. Stir and mix the interface mortar of Boweit grindstone with water evenly, and then pour the material on the ground.

2. Scrape evenly, and the dosage should be about 2mm (the flatness, strength, and weather temperature of the concrete directly affect the dosage of the interface material, and the fluctuation of 0.1 belongs to the normal range)

3. When the roller is painted, the direction should be consistent, the weight should be appropriate, and the brush pattern should be uniform and no omissions. (If there is any omission and insufficient filling, it will cause the phenomenon of sanding and hollowing of the trowel)

Quality standards and control measures

1. Strictly abide by the standard construction of the Powerway construction process instruction manual, and should be uniform, without leakage and without impurities.

2. Ingredients are strictly in accordance with the proportioning requirements, and the interface agent is well controlled.

3. It can be laid before the interface agent reaches the standard, which can effectively control the hollowing and cracking of inorganic terrazzo.

The above construction steps are completed.

The third step of the construction process of inorganic terrazzo floor: color separation and pouring

[Guide]: At present, many commercial places like to use patterns of different colors to distinguish different areas, which looks like a beautiful picture from a distance, and most of such ground effects are drawn by inorganic terrazzo floors. Inorganic terrazzo floor brings us more than traditional resistance

At present, many commercial places like to use patterns of different colors to distinguish different areas, which looks like a beautiful picture from a distance, and most of such ground effects are drawn by inorganic terrazzo floors. Inorganic terrazzo floor brings us not only the traditional durability, but its design is gradually being discovered by designers.

Ready to work

1. When making patterns, you can request the material company or advertising company to engrave the mold according to the size of the pattern.

2. After the mold is carved, it is combined with the drawing, and the construction plan is made according to the pattern after confirming that it is correct.

3. Prepare materials and construction tools for the next process (including trowels, sand mixers, gasoline drums, trowels, etc.)

Separated pouring

1. After the surface layer is flattened, determine which color is to be done first and then line up according to the size of the drawing.

2. Place the width control line, which generally exceeds the paving area by 2~3cm.

3. Fix the pattern firmly on the ground with nails or other adhesives

4. Lay grid strips at the line-out position and pull the line to correct and level, and fix it with grindstone mortar.

5. Use a floor cutter to cut straight and straight at the position of the elastic line.

6. The cutting depth is 5~7mm. It must be cleaned after cutting, and no chipping or pollution is required.

The above construction steps are completed.

The fourth step of the construction process of inorganic terrazzo floor: seamless paving

[Guide]: The most important step for the inorganic terrazzo floor to be seamless as a whole is to spread the grindstone mortar evenly on the ground, so as to achieve an overall seamless effect. There must be no mistakes in the control of the steps before paving, and the Powett construction workers should be strictly followed.

The most important step for the inorganic terrazzo floor to be seamless as a whole is to spread the grindstone mortar evenly on the ground to achieve an overall seamless effect. There must be no errors in the control of the steps before paving, and should be carried out in strict accordance with the Powett construction process instruction manual, so as to prevent the problems of hollowing and cracking to the greatest extent.

Mixing Bowei Te grindstone mortar

1. Use special mixing equipment to agitate Boweite grinding stone mortar.

2. Fully stir in the agitator according to the product description and the strict water-cement ratio.

3. The stirring time is not less than 3 minutes, the static slurry is 1 minute, and the stirring is 1 minute.

4. Stirring is required until there is no agglomeration, and its fluidity should be observed to ensure concentration.

Precautions

1. Excessive stirring will produce color difference, so you need to pay attention to the scale.

2. Adding too much water will reduce the strength, so you can't increase the water at will.

Pouring, paving

1. The mixed inorganic terrazzo floor material is poured on the ground

2. Use a scraper with thickness control to control the thickness, and the paving thickness is 10mm-12mm after compaction.

3. Avoid direct sunlight and wind, and control the temperature in indoor construction.

4. Let it stand for 2 minutes to let the air bubbles out, and then use a defoaming roller to defoam.

5. Laying horizontally with infrared level, the level error is within 1-2mm.

6. Use a 3-meter rod for testing to ensure that the flatness is within 1~2mm.

Quality standards and control measures

1. Inorganic terrazzo materials should be uniform, flat, free of hollow drums, pollution, and variegated.

2. Strictly control the material ratio, and the mixing time should be controlled within 1 to 3 minutes.

3. Ensure that the thickness of the inorganic terrazzo floor layer is 10mm-12mm, and the flatness is within 1~2mm

The above construction steps are completed.

The fifth step of the construction process of inorganic terrazzo floor: ground maintenance

[Guide]: Since the inorganic terrazzo floor adopts the cast-in-place construction technology, the maintenance time is only 8 hours, and the impact on the construction period is minimal. However, this step should not be ignored. The quality of maintenance directly affects the progress of later ground polishing, so it should not be taken lightly.

Since the inorganic terrazzo floor adopts the cast-in-place construction technology, the maintenance time is only 8 hours, and the impact on the construction period is minimal. However, this step should not be ignored. The quality of maintenance directly affects the progress of later ground polishing, so it should not be taken lightly.

Maintenance work

1. Use a flat mop or a rag to evenly apply Bowete's special protective agent to seal and maintain

2. Prevent unrelated personnel from entering the floor maintenance area when the floor is not completely cured

3. It is found that the inorganic terrazzo floor is polluted and should be cleaned up in time to avoid affecting the impression of the floor after completion.

Maintenance requirements

1. The maintenance time of inorganic terrazzo floor is generally more than 8 hours (according to the indoor temperature and the curing of the floor)

2. A variety of tools should be selected reasonably according to the size of the cleaning work surface to improve work efficiency.

3. If the ground is narrow or there are many stacked facilities, dust pushing should be abandoned and mop dust removal should be used.

4. Tools such as brooms, floor mops, dust pushers, etc. should be intact. If damaged, they should be replaced in time to ensure the efficiency of the cleaning work.

5. When mopping the floor, you should press one frame at a time to ensure that the drag is not missed. The size of the pressing range is one-third.

6. When cleaning, mopping the floor and pushing dust on the wall and the floor, it should be carried out in a smooth manner.

The above construction steps are completed.

The sixth step of the construction process of inorganic terrazzo floor: ground polishing

[Guide]: Inorganic terrazzo floor polishing is to remove the scum layer on the surface. In order to improve the adhesion, we need to rough, intermediate and fine polish the ground.

Inorganic terrazzo floor polishing is to remove the scum layer on the surface. Many invisible substances and uneven places will affect the overall engineering quality in the later stage. Therefore, in order to improve the adhesion, we need to rough, medium, and grind the ground. Fine grinding treatment.

1. Ground curing

1. Shake the solution evenly and pour it into a low-pressure sprayer, and then spray it evenly with saturation.

2. To keep the surface moist, apply water to moisten the local viscous solution and spread it evenly.

3. If the ground dries too quickly within 20 minutes, it should be sprayed a second time in time.

4. Generally, at 20°C and with good air circulation, the solution will completely penetrate and dry for 2-4 hours.

5. If white residue appears during the drying process, it should be scrubbed with water immediately.

2. Coarse grinding treatment

1. During rough grinding, a 2m ruler should be used to test the flatness of the ground.

2. Grind the high part until the flatness meets the standard, and the rough grinding should grind out all the bone textures.

3. The flatness of rough grinding is controlled within 2mm-1 mm

4. The 50-150 mesh diamond grinding disc is open and polished to make the ground level and smooth.

3. Middle grinding treatment

1. After the rough grinding is checked and meets the requirements, use the grinder to assemble 200 mesh resin grinding discs for medium grinding.

2. Use a small portable grinder to repair small parts such as walls and columns. A vacuum cleaner must be used for polishing.

3. The grinding sequence and operation method of the middle grinding are the same as those of the rough grinding. It is mainly used to eliminate the wear marks left by the rough grinding and make the natural aggregate texture on the surface of the colored sand layer of the inorganic terrazzo floor more clear and natural.

4. Fine grinding and polishing

1. After the middle grinding machine is checked that there is no missing grinding and meets the requirements, the grinding machine can be equipped with 300 mesh resin grinding discs for fine grinding and polishing.

2. Fine grinding and polishing require the surface of the inorganic terrazzo floor and the aggregate texture of the stone to be uniform, fine, smooth, and bright.

3. After the 300-mesh grinding is completed, use 500-3000-mesh resin grinding discs for grinding and polishing, the method is the same as above, and the cleaning work is done after completion.

5. Quality standards and control methods

1. The surface is smooth, without abrasion marks, the texture is uniform and delicate, the color is consistent, and there is reflection.

2. Strictly follow the polishing sequence of the Powett instruction manual, and control the polishing speed and time.

3. Special personnel should follow up and inspect the whole process to control the polishing quality of small parts such as walls and pillars.

The above construction steps are completed.

The seventh step of the construction process of inorganic terrazzo floor: anti-seepage crystallization

[Guide]: The anti-seepage crystallization step will block the capillaries and micro cracks of the concrete, and can withstand 10 meters of water without being penetrated. It is very suitable for swimming pools, outdoor parks and other places.

The purpose of anti-seepage crystallization is to improve the compactness of the base concrete of the inorganic terrazzo floor, so as to achieve the effect of waterproofing. The anti-seepage crystallization step will block the capillaries and micro cracks of the concrete, and can withstand 10 meters of water without being penetrated. It is very suitable for swimming pools,

Outdoor parks and other places.

Surface cleaning of inorganic terrazzo floor

1. After the fine grinding is completed, a vacuum cleaner should be used to thoroughly clean the floor.

2. Use a high-pressure water gun to clean the ground after vacuuming

3. After spraying the ground wet, use the dust pusher to clean it from one direction, and then use a water suction machine to absorb water.

Precautions:

Pay special attention to the corners of the wall, and the closed layer construction can be carried out after the ground is dry and meets the requirements after inspection.

Inorganic terrazzo anti-seepage crystallization

1. Prepare inorganic terrazzo floor anti-seepage crystalline materials according to the construction ratio

2. After construction, the real and natural beauty of inorganic terrazzo floor sand aggregate is presented

3. After the general anti-seepage crystalline layer is scraped, it is sealed and cured for 8-12 hours and then repeated batch scraping once.

4. In order to get a better decoration effect, it can be done twice according to the actual situation

Quality Standard

The texture is uniform, bright and clear, no omissions, consistent color, no scratches, pollution and variegated

Control Method

1. Strictly control the polishing and dust suction effect of the grindstone surface to ensure that the surface is clean and free of dust, pits and other quality defects.

2. When the anti-seepage crystalline layer is not completely solidified, it should be closed and maintained to avoid pollution and scratches, which will affect the look and feel of the floor.

The above construction steps are completed.

The eighth step of the construction process of inorganic terrazzo floor: surface polishing

[Guide]: 1.300 mesh grinding disc polishing 2.500 mesh grinding disc polishing 3.1000 mesh grinding disc polishing 4.2000 mesh grinding disc polishing 5.3000 mesh grinding disc polishing, this step is very important, and it is related to the main factor of whether the inorganic terrazzo floor is bright in the later stage.

Inorganic terrazzo polishing is a very important step. After many projects are completed, it is found that the gloss of the ground does not meet the requirements of Party A. A large part of the reason is that the polishing step is wrong. Therefore, the polishing part must be carried out in strict accordance with the construction process, and the steps must not be omitted privately.

1. Polishing requirements for 300-500 mesh inorganic terrazzo

1. Put a small amount of water on a 300-500 mesh resin dry polishing pad for the first polishing, and polish all the sealing layer until the surface of the aggregate is exposed.

2. The equipment needs to be polished in a straight line and at a constant speed, and polished horizontally and vertically, until the resin is polished clean.

Precautions

The polishing machine should not stay at will. The machine will move forward at a constant speed. After completion, clean the floor and carefully check whether there is any residual resin on the floor. The floor feels fine and has a certain gloss.

2. Polishing requirements for 1000-3000 mesh inorganic terrazzo

1. Put a small amount of water on a 1000 mesh resin dry grinding pad for polishing, which requires cross polishing. This process also directly affects the subsequent polishing effect, so this polishing is particularly important.

2. The steps for 2000-3000 meshes are the same as those for 1000 meshes

3. The machine advances at a constant speed. After completion, clean the ground, and carefully check whether there is any part of the ground that is not delicate to the touch. The touch of the ground is very fine and reflective.

Precautions

Each of the above steps must be waterproof and polished to prevent the high temperature from polishing, which will cause the discoloration of the water abrasive sheet and cause discoloration of the ground. After the above steps are completed, use a polishing pad to put a small amount of polishing liquid for polishing.

The above construction steps are completed.

The ninth step of the construction process of inorganic terrazzo floor: filling treatment

[Guide]: Inorganic terrazzo floor joint filling treatment is the last step and the most critical step. Many construction projects will be overturned at this step, so everyone must read it carefully.

After the first eight steps are completed, the final step of caulking is required. After completion, the entire ground will be delivered to Party A for acceptance. But many projects will have problems in this last step, not because it is difficult to work in this step, but because this step requires patience and carefulness.

1. Caulking treatment

1. The two-component high-performance inorganic terrazzo floor elastic sealing paste is used for sealing, and the construction is carried out by professionals.

2. Carry out a comprehensive inspection before processing the expansion joints, remove and loosen the dust and other debris in the compartment seams, use a vacuum cleaner to bounce the threads on both sides of the compartment seams, and paste paper tape.

3. Prepare the inorganic grindstone floor elastic glue with similar floor color, and use a professional glue gun to fill the glue. When filling the glue, pay attention to the drag speed to ensure the density and surface flatness of the glue, and it should not stick to the paper surface glue. On the floor, ensure the beauty of the sub-bin seams.

4. The seam width should be 5~6mm, the depth should be 10~15mm, and the width should be consistent, clear and straight.

2. Matters needing attention

1. Strictly abide by the regulations and systems for safe electricity use in building construction to ensure the smooth progress of the construction process.

2. Follow the principle of ensuring quality while ensuring safety

3. Strictly control the thickness and flatness of the polishing, which should be smooth and free of wear marks, or wear and tear through the floor.

4. Before the inorganic terrazzo floor is sealed, the surface condition of the grindstone layer should be strengthened to ensure that the surface is smooth, the color of the aggregate is clear, and the color is uniform.

5. Strictly control the trimming, polishing, polishing and closing of the entrance and exit, wall, column, door and sub-storage joints, so that the lines are clear and straight.

6. Strengthen the inspection of the construction process, each process is interlocking, abide by the principle that the previous process is unqualified and shall not be carried out in the next process, and the quality is strictly controlled.

7. Focus on controlling the gradation, color and thickness of the inorganic terrazzo floor coating of the sealing layer to ensure no scratches, no pinhole pockmarked surface, smooth surface and consistent texture.

The above construction steps are completed.

Copyright © 2022 Foshan Bayard Building Material Co., Ltd. | All Rights Reserved